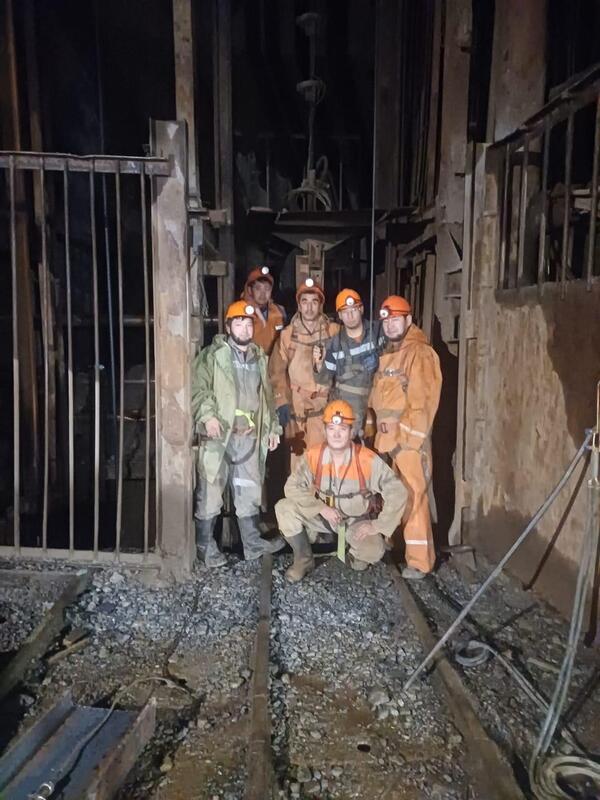

The shaft is the heart of the AltynEx Company mine. Scheduled maintenance of its structures is always a major event, as the reliability of the reinforcement and the proper functioning of the equipment determine not only production targets but also personnel safety. In August of this year, employees of the Shaft Repair and Maintenance Section of the Chief Mechanic's Department carried out a comprehensive program at the Kapitalnaya mine. Over the course of the month, the shaft's metal reinforcement structures were replaced, the spur beams and rail guides were upgraded, the skip discharge unit at the "0" mark and the discharge curves were repaired, and the P-804 apron feeder was repaired, including the replacement of chains, pallets, and drive sprockets. At the +10-meter level, repairs were carried out on the feeder hopper, installing new lining sheets and grates. The work concluded with the replacement of the brake cables in the shaft cage section, which ensure the reliable and safe operation of the hoisting system during the descent and ascent of personnel into the cages. Communications were also adjusted, including a complete overhaul of the wired public address system for the working levels and the mine cage alarm system.

Nurbolat Sadykov, Chief Mechanic, AltynEx Company

All work required close coordination between mechanics, power engineers, and industrial safety specialists. Thanks to this coordinated effort, the repairs were completed on time, and the mine is now operating stably and as planned.

Nurbolat Sadykov, Chief Mechanic, AltynEx Company

All work required close coordination between mechanics, power engineers, and industrial safety specialists. Thanks to this coordinated effort, the repairs were completed on time, and the mine is now operating stably and as planned.